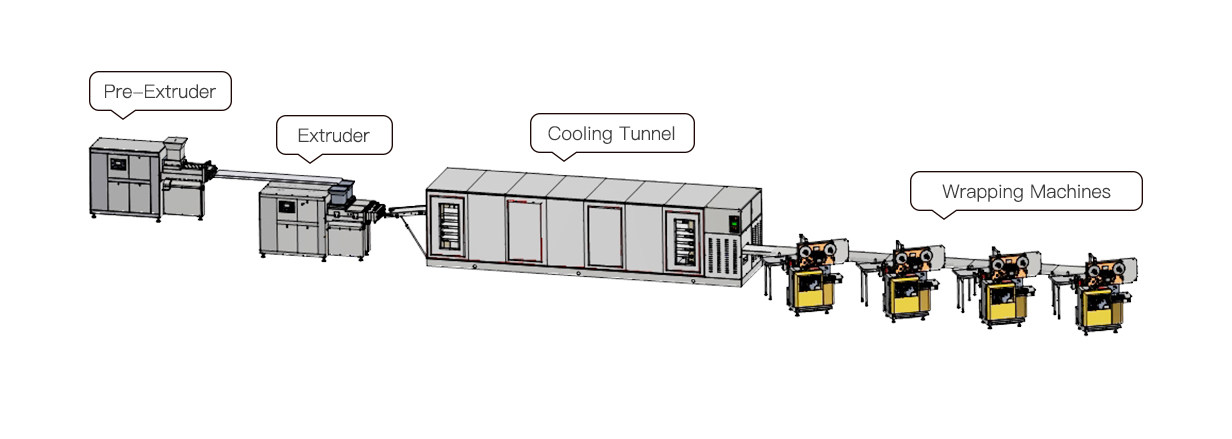

Chewy Candy And Bubble Gum Line

Chewy Candy And Bubble Gum Line

-

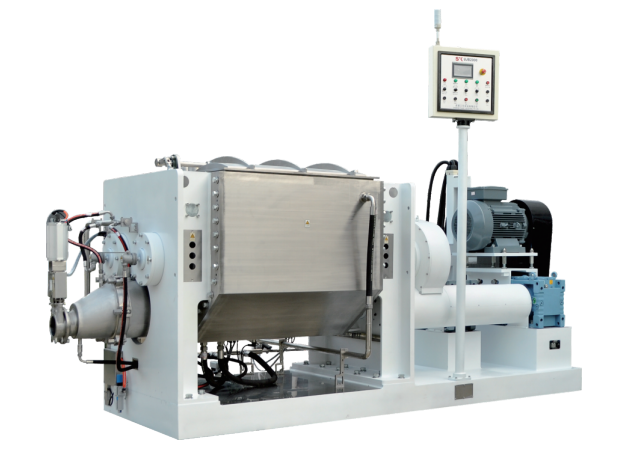

UJB2000 MIXER WITH DISCHARGING SCREW

UJB serial mixer is a confectionery material mixing equipment, which meets international standard, suitable for producing toffee, chewy candy, gum base, or mixing needed confectioneries

-

ULD COOLING TUNNEL

ULD series cooling tunnel is the cooling equipment for candy production. The conveyor belts in cooling tunnel are driven by Germany brand SEW motor with reducer, Speed adjustment via Siemens frequency converter, cooling system equipped with BITZER Compressor, Emerson electronic expansion valve, Siemens proportion triple valve, KÜBA cool air blower, surface cooler device, temperature and RH adjustable via PLC control system and touch screen HMI

-

TRCJ EXTRUDER

TRCJ extruder is for soft candy extrusion including chewing gums, bubble gums, toffees, soft caramels and milky candies. Contacting parts with products are made of SS 304. TRCJ is equipped with double feeding rollers ,-shaped double extrusion screws, temperature-regulated extrusion chamber and can extrude one or two-color product

-

UJB MIXER OF MODEL 300/500

UJB serial mixer is international standard confectionery material mixing equipment for chewing gums, bubble gums and other mixable confectioneries

-

UJB250 MIXER WITH DISCHARGING SCREW

UJB serial mixer is international standard confectionery material mixing equipment for toffees, chewy candies, or other mixable confectioneries

-

BZM500

BZM500 is a perfect high-speed solution which combines both flexibility and automation for wrapping products such as chewing gum, hard candies, chocolate in plastic/paper boxes. It has high degree of automation, including product aligning, film feeding & cutting, product wrapping and film folding in fin-seal style. It is a perfect solution for product sensitive to humidity and effectively extending the product shelf life

-

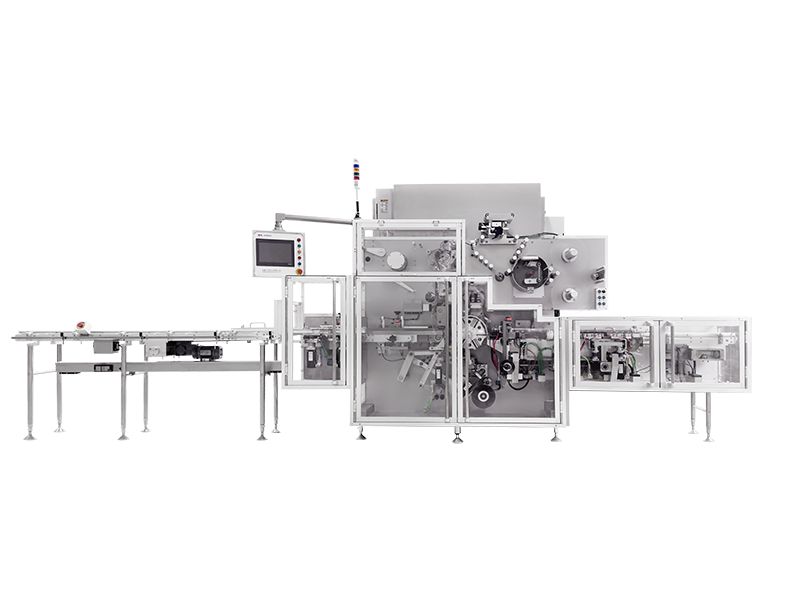

BFK2000MD FILM PACK MACHINE IN FIN SEAL STYLE

BFK2000MD film pack machine is desined to pack confectionery/food-filled boxes in fin seal style. BFK2000MD is equipped with 4-axis servo motors, Schneider motion controller and HMI system

-

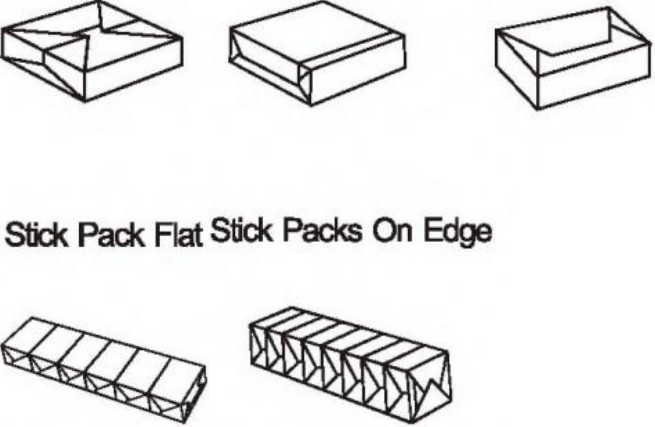

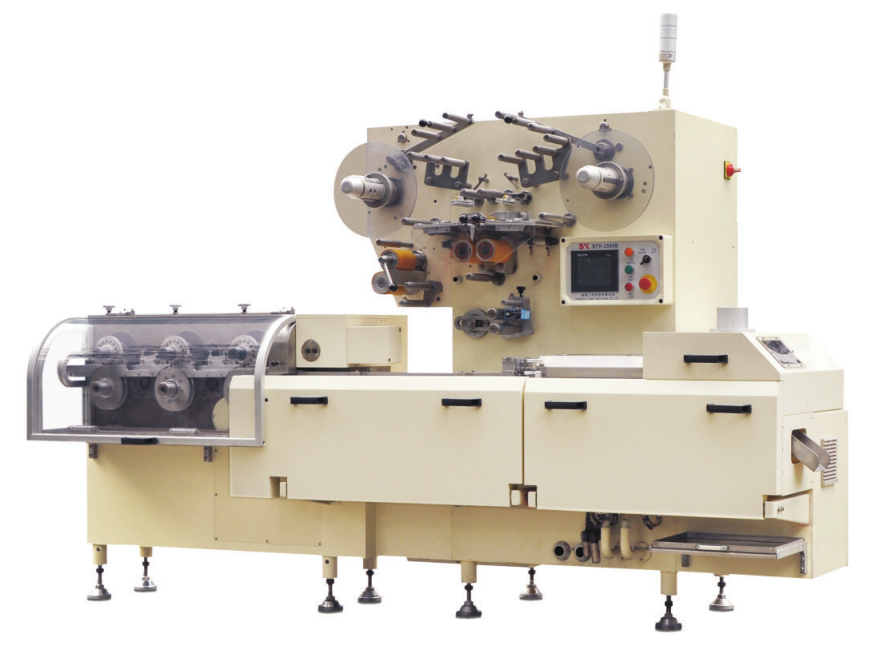

BZW1000&BZT800 CUT&WRAP MULTI-STICK PACKING LINE

The packing line is an excellent solution of forming, cutting and wrapping for toffees, chewing gum, bubble gum, chewy candies, hard and soft caramels, which cut&wrap products in bottom fold, end fold or envelop fold and then overwrapping stick on edge or flat styles (Secondary packaging). It meets hygienic standard of confectionery producing, and CE safety standard

This packing line consists of one BZW1000 cut&wrap machine and one BZT800 stick packing machine, which are fixed on same base, to achieve rope cutting, forming, individual products wrapping and stick wrapping. Two machines are controlled by same HMI, which are easy to operate and maintain

-

BZW1000 CUTTING&WRAPPING MACHINE

BZW1000 is an excellent forming, cutting and wrapping machine for chewing gums, bubble gums, toffees, hard and soft caramels, chewy candies and milky candy products.

BZW1000 has several functions including candy rope sizing, cutting, single or double paper wrapping (Bottom Fold or End Fold), and double twist wrapping

-

BZH600 CUTTING & WRAPPING MACHINE

BZH is designed for cut and fold wrap chewing gums, bubble gums, toffees, caramels, milky candies and other soft candies. BZH is capable to execute candy rope cutting and fold wrapping (end/back fold) with one or two papers

-

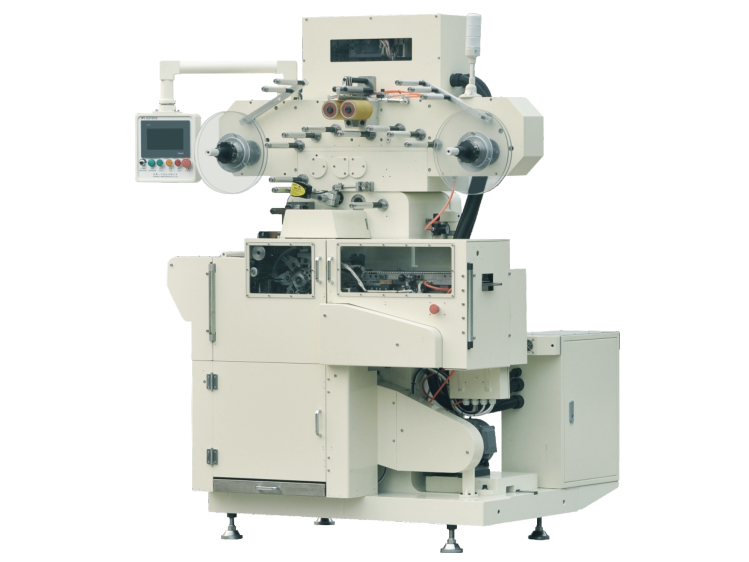

BFK2000B CUT & WRAP MACHINE IN PILLOW PACK

BFK2000B cut & wrap machine in pillow pack is suitable for soft milk candies, toffees, chews and gum products. BFK2000A is equipped with 5-axis servo motors, 2 pieces of converter motors, ELAU motion controller and HMI system are employed