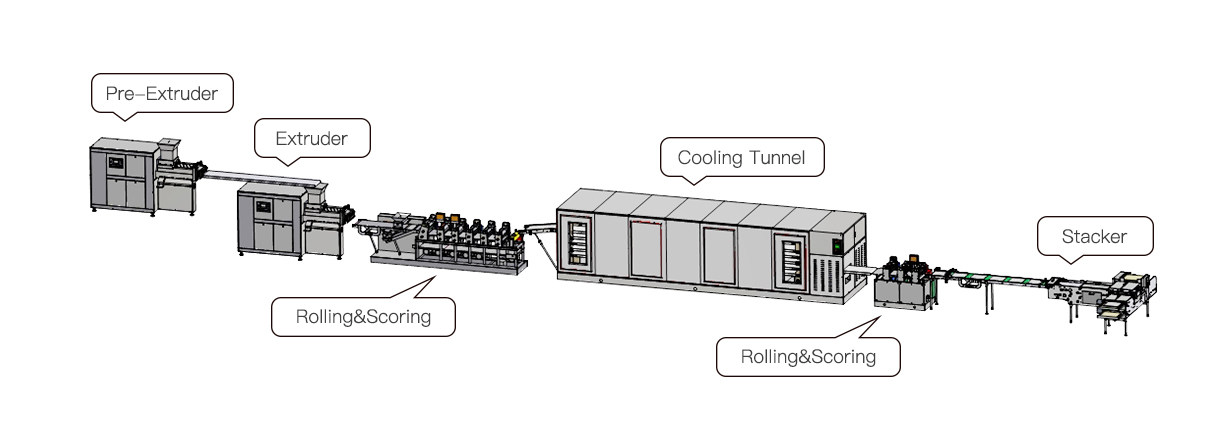

Chewing Gum Line

Chewing Gum Line

-

TRCY500 ROLLING AND SCORLLING MACHINE

TRCY500 is essential production equipment for stick chewing and dragee chewing gum. The candy sheet from extruder is rolled and sized by 6 pairs of sizing rollers and 2 pairs of cutting rollers

-

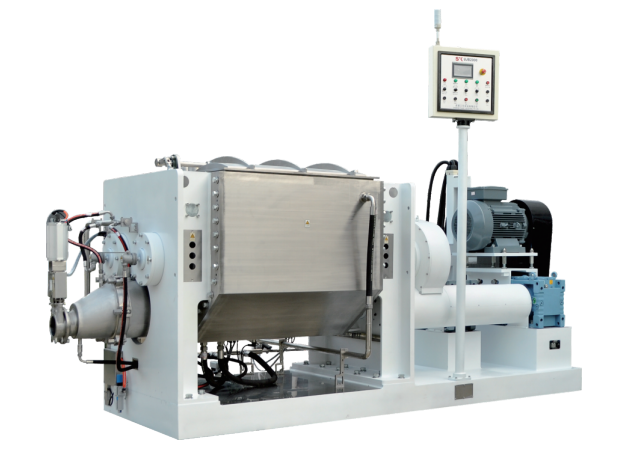

UJB2000 MIXER WITH DISCHARGING SCREW

UJB serial mixer is a confectionery material mixing equipment, which meets international standard, suitable for producing toffee, chewy candy, gum base, or mixing needed confectioneries

-

TRCJ EXTRUDER

TRCJ extruder is for soft candy extrusion including chewing gums, bubble gums, toffees, soft caramels and milky candies. Contacting parts with products are made of SS 304. TRCJ is equipped with double feeding rollers ,-shaped double extrusion screws, temperature-regulated extrusion chamber and can extrude one or two-color product

-

UJB MIXER OF MODEL 300/500

UJB serial mixer is international standard confectionery material mixing equipment for chewing gums, bubble gums and other mixable confectioneries

-

ZHJ-SP30 TRAY PACKING MACHINE

The ZHJ-SP30 tray cartoning machine is a special automatic packaging equipment for folding and packaging rectangular candies such as sugar cubes and chocolates that have been folded and packaged.

-

ZHJ-SP20 TRAY PACKING MACHINE

ZHJ-SP20TRAY PACKING MACHINE is especially designed for tray packing already-wrapped stick chewing gum or rectangular candy products

-

BFK2000MD FILM PACK MACHINE IN FIN SEAL STYLE

BFK2000MD film pack machine is desined to pack confectionery/food-filled boxes in fin seal style. BFK2000MD is equipped with 4-axis servo motors, Schneider motion controller and HMI system

-

BZT150 FOLD WRAPPING MACHINE

BZT150 is used for folding packed stick chewing gum or candies into a carton

-

BZK STICK WRAPPING MACHINE FOR DRAGEE CHEWING GUM

BZK is designed for dragee in stick pack that multiple dragees(4-10dragees) into one stick with one or two papers

-

BZK400 STICK WRAPPING MACHINE FOR DRAGEE CHEWING GUM

BZT400 stick wrapping machine is designed for dragee in stick pack that multiple dragees (4-10dragees) into one stick with single or dual pieces of papers