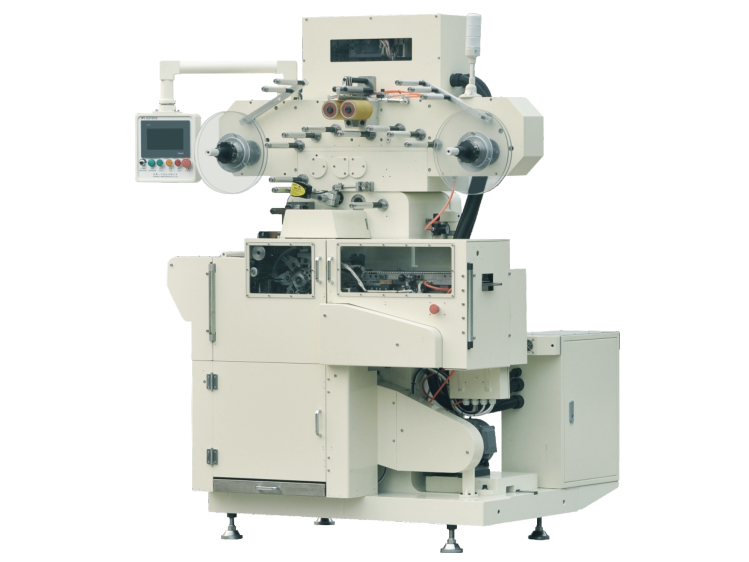

BFK2000I FLOW PACKING MACHINE

1. MAG-LEV carrier quantity is configurable based on production capacity demands

2. Recirculating workstation design significantly optimizes floor space utilization

1. Quick-change modules enable instant switching of carton profiles and dimensions

2. Selective activation of carton gripping channels supports seamless transition between high/low packaging speeds

1. Tool-free clamping system on MAG-LEV carriers enables rapid fixture changeovers, cutting setup time by 60%

2. Universal fixtures adapt to multi-size cartons, eliminating change parts and reducing changeover time by 50%

3. Dynamically adjustable glue guns allow on-the-fly size switching for rapid product format changes

Special features

- Modular full-servo drive: Independent servo control on critical stations including product infeed, longitudinal sealing, cross sealing, film feeding, and automatic center lining ensures precise response and high synchronization

- Ergonomic and optimized layout: Compact, rational arrangement of functional units facilitates easy operation, cleaning and routine maintenance

- Cross-seal unit with dual inward-fold creasing: Produces neat, uniform bag ends for improved appearance and seamless downstream cartoning

- Optional folding & heating unit: Enhances package aesthetics and compatibility with subsequent cartoning systems

- Automatic reel loading system: Pneumatically actuated for quick roll changes and minimized downtime

- Centralized lubrication system: Ensures long-term operational reliability and reduces maintenance requirements.

- CE compliant

Output

- Max. 200 packs/min

Product Measurements

- Length: 50-200 mm

- Width: 20-80 mm

- Thickness: 5-30 mm

Connected Load

- 25 KW

Utilities

- Compressed air consumption:4 L/min

- Compressed air pressure:0.4~0.6 MPa

Wrapping Materials

- Heat sealable foil

- PP film

- PET film

Wrapping Material Dimensions

- Reel dia.:Max. 360 mm

- Core dia.:76 mm

- Reel width: 60-220 mm

Machine Measurements

- Length:4000mm

- Width:1800mm

- Height:2300mm

Machine Weight

- 4000kg