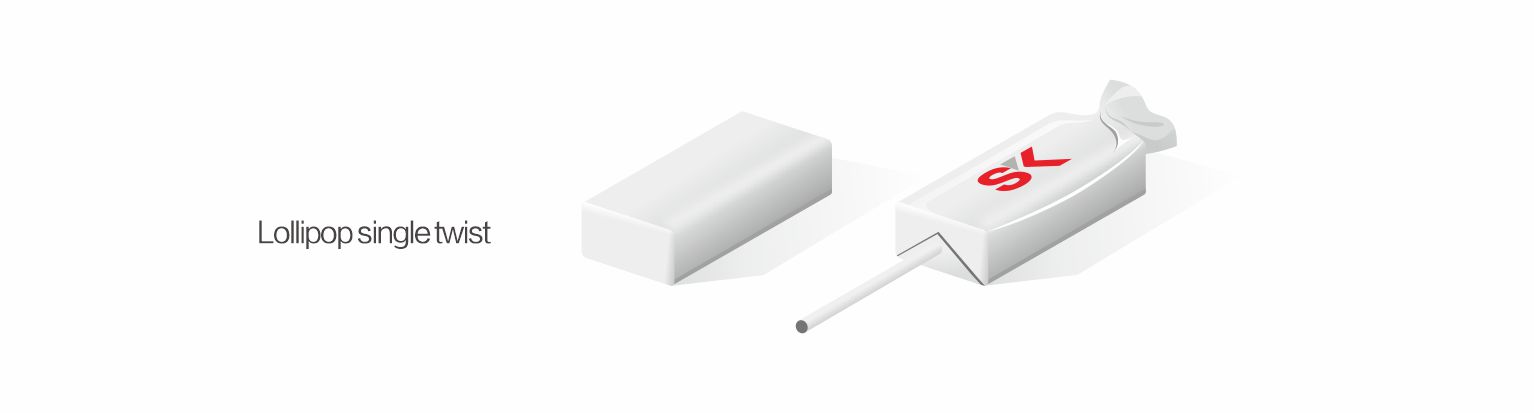

BZH-N400 Fully Automatic Lollipop Cutting and Packaging Machine

Special features

●The transmission system uses an inverter for stepless speed regulation of the main motor

●No product no wrapping materials; no product no sticks

●Stops automatically on candy jam or wrapping material jam

●No-stick alarm

●The whole machine adopts PLC control technology and a touch-screen HMI for parameter setting and display, making operation convenient and automation level high

●Equipped with a photoelectric tracking positioning device, enabling precise cutting and packaging of wrapping material to ensure pattern integrity and aesthetic appearance

●Utilizes two paper rolls. The machine is equipped with an automatic splicing mechanism for wrapping material, allowing automatic splicing during operation, reducing roll change time, and improving production efficiency

●Multiple fault alarms and automatic stop functions are set throughout the machine, effectively protecting personnel and equipment safety

●Features such as "no wrapping without candy" and "automatic stop on candy jam" save packaging material and ensure product packaging quality

●Reasonable structural design facilitates cleaning and maintenance

Output

● Max. 350 pieces/min

Product Dimensions

● Length: 30 – 50 mm

● Width: 14 – 24 mm

● Thickness: 8 – 14 mm

● Stick Length: 75 – 85 mm

● Stick Diameter: Ø 3 ~ 4 mm

Connected Load

●8.5 kW

- Main Motor Power: 4 kW

- Main Motor Speed: 1,440 rpm

● Voltage: 380V, 50Hz

● Power System: Three-phase, four-wire

Utilities

● Compressed Air Consumption: 20 L/min

● Compressed Air Pressure: 0.4 ~ 0.7 MPa

Wrapping Materials

● PP film

● Wax paper

● Aluminum foil

● Cellophane

Wrapping Material Dimensions

● Max. Outer Diameter: 330 mm

● Min. Core Diameter: 76 mm

Machine Measurements

● Length: 2,403 mm

● Width: 1,457 mm

● Height: 1,928 mm

Machine Weight

● Approx. 2,000 kg